imc Online FAMOS - Ergebnisse in Echtzeit

Echtzeitanalyse-Plattform für imc Messgeräte

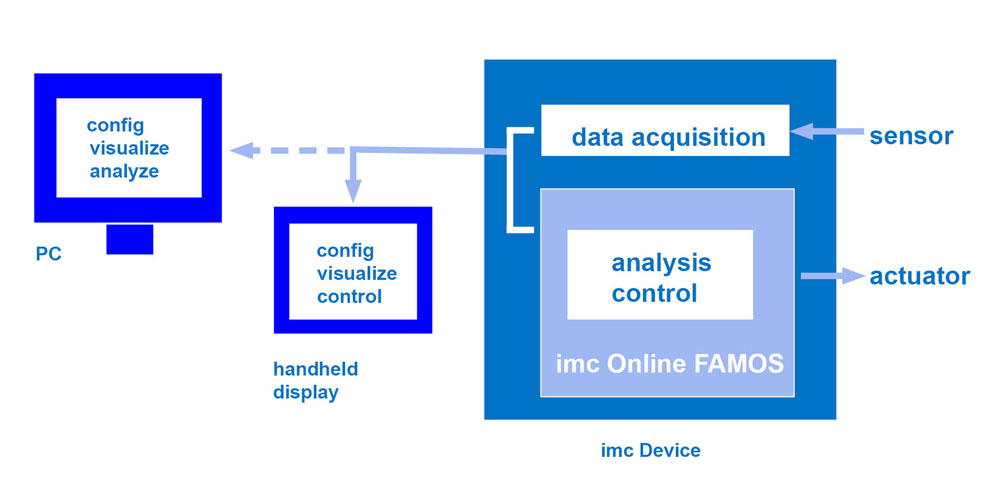

Wenn Sie nicht nur Messdaten, sondern fertige Ergebnisse in Echtzeit erhalten möchten, profitieren Sie von einer der wichtigsten Erweiterungen für unsere Messdatenerfassungssysteme: imc Online FAMOS.

- Messdatenanalyse während der Messung

- Echtzeitreaktion des Messgerätes

- Datenreduktion und Statistiken Online

Online calculations

Verrechnen & Analysieren

imc Online FAMOS erlaubt es, eingehende Messdaten unmittelbar in Resultate zu verwandeln und dies ohne PC direkt im Messgerät. Zeitsynchron und deterministisch können von imc Online FAMOS kanalübergreifende mathematische Berechnungen durchgeführt werden, Statistiken angelegt, Vergleiche getätigt oder anspruchsvolle Steuer- und Regleralgorithmen berechnet und ausgeführt werden. Somit spart imc Online FAMOS Zeit und Geld, denn eine nachträgliche Auswertung entfällt ganz oder wird erheblich verkürzt.

Schnelle Entscheidungen vor Ort

Häufig hängt der Fortgang eines Tests direkt von den aktuell erzielten Messwerten und den daraus ermittelten Analyse-Ergebnissen ab. imc Online FAMOS hilft, Verzögerungen durch langwierige Auswertung zwischen Datenerfassung und Entscheidungsprozess zu vermeiden. Die Echtzeitanalyseplattform liefert kontinuierlich zur laufenden Messung fertige Analyse-Ergebnisse („Immediate Results“). So kann z.B. ein Testfahrer bereits während der Messfahrt an Hand der Echtzeitanalyse-Ergebnisse erkennen, ob der Test erfolgreich war, ohne eine nachfolgende Auswertung abwarten zu müssen.

Steuern und Regeln - in Echtzeit reagieren

imc Online FAMOS steuert die unmittelbare Reaktion des Messgerätes auf gemessene Ereignisse in wenigen 100 µSekunden. Dadurch ist das Messsystem in der Lage in den Ablauf von Tests in Echtzeit einzugreifen und beispielsweise über digitale oder analoge Ausgänge den Prüfablauf zu beinflussen. Durch die Nutzung von imc Online FAMOS wird aus jedem imc Messgerät ein vollständiges Mess-, Steuer- und Regelsystem. Ohne zusätzliche externe Hardware. Das spart Zeit und Geld.

Autark und ohne PC

Weder die Live-Datenanalyse noch die Anzeige der Ergebnisse erfordern einen PC: Die Analyse wird auf der eingebetteten Prozessor-Plattform des autarken imc Messgeräts ausgeführt. Zur Datenanzeige genügt ein imc Geräte-Display das zusätzlich auch Interaktion wie z.B. Messung starten/stoppen ermöglicht.

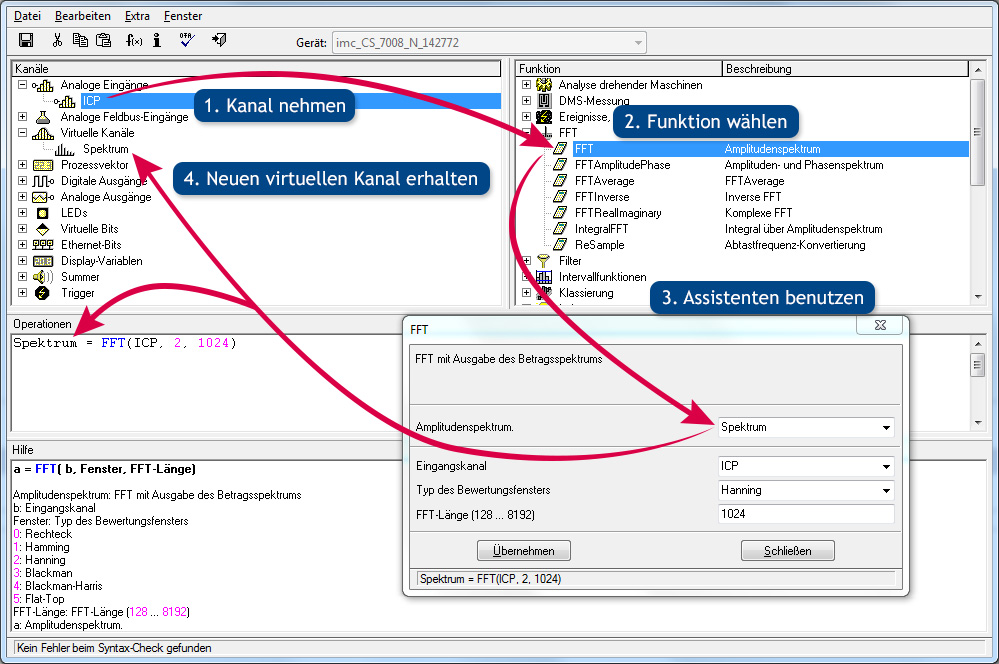

So einfach geht es

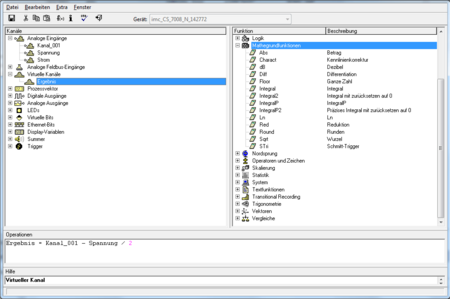

Insgesamt stehen mehr als 100 verschiedene Funktionen zur Verfügung mit denen ein imc Messgerät während der Datenaufnahme vielfältige Ergebnisse produzieren und speichern kann. Mit wenigen Mausklicks werden alle Funktionen über einen Bedienassistenten erreicht und das Messgerät in kürzester Zeit konfiguriert. Die kontinuierlich berechneten Ergebnis-Kanäle können darüber hinaus auch zur Definition von Trigger-Bedingung herangezogen werden. So können Anwender präzise, zielgerichtete und effiziente Messung durchführen und fertige Ergebnisse während der Messung erzielen!

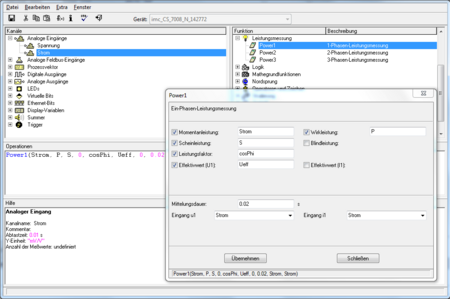

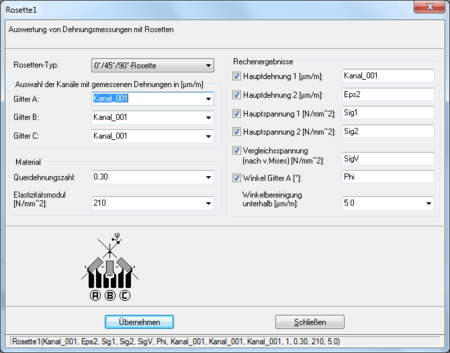

Umfangreiche Funktionsbibliothek

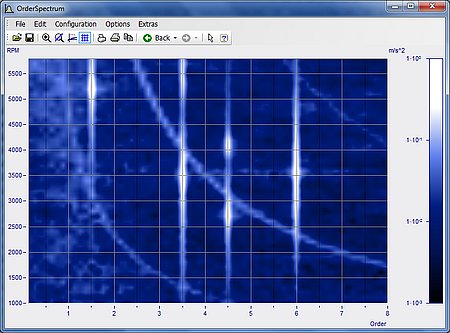

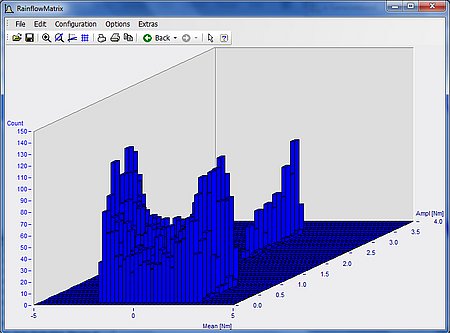

Für die Datenanalyse steht eine umfassende Sammlung von Standardfunktionen zur Verfügung wie z.B. Leistungsberechnungen, statistische Auswertungen oder mathematische Grundfunktionen. Daneben sind spezielle Anwendungsgebiete abgedeckt - wie die Ordnungsanalyse, Akustik-Bewertungen, DMS-Rosettenschaltungen, Klassier-Algorithmen für die Festigkeitsanalyse, digitale Filter oder nichtlineare Kennlinien-Bewertungen.

Mathematische Grundfunktionen

- Sämtliche mathematische Grundfunktionen von Basis-Arithmetik bis zum Differenzieren, Integrieren oder Kennlinien-Korrektur stehen zur Verfügung

- Berechnungen werden wie bei einem Taschenrechner notiert

- Ergebnisse werden in Form virtuelle Kanäle ausgegeben und können gespeichert und weiter verrechnet werden

Steuern und Regeln - in Echtzeit reagieren

imc Online FAMOS steuert die unmittelbare Reaktion des Messgerätes auf gemessene Ereignisse in wenigen 100 µSekunden. So kann ein Prüfstands-Bediener über den aktuellen Zustand einer Prüfung/Messung unmittelbar informiert werden, während das Messgerät, ohne merkliche Verzögerung, eigenständig in den Ablauf des Tests eingreifen kann, z. B. über digitale oder analoge Ausgänge.

Durch die Nutzung von imc Online FAMOS wird aus jedem imc Messgerät ein vollständiges Mess-, Steuer- und Regelsystem. Ohne zusätzliche externe Hardware. Das spart Zeit und Geld.